- Home

- Oil Hose

- Home

- Products

- Industries

- Company

- Contact Us

- Home

- Products

- Industries

- Company

- Contact Us

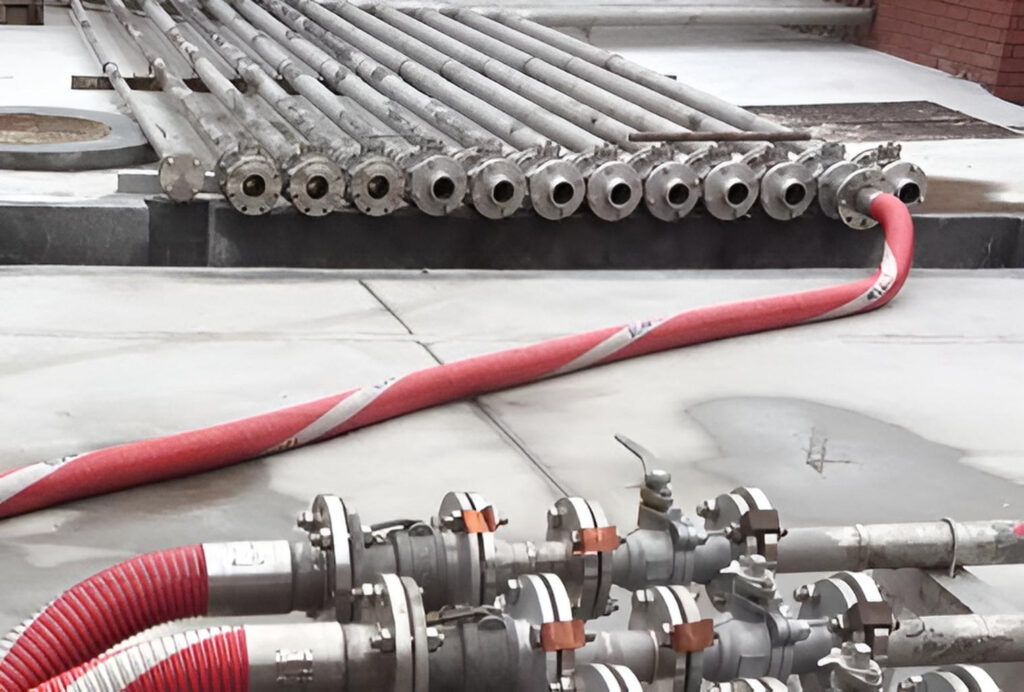

Oil composite hose is applied to the suction and discharge of fuel oil products such as gasoline, diesel, liquefied petroleum gas (LPG), etc. It has good antistatic properties and can withstand high pressure, abrasion and high temperature. In the suction or discharge operation, the inner coil of the hose supports the hose wall to prevent the hose from collapsing under the action of suction. The outer coil gives the hose resistance to pressure, protecting the hose from external wear and tear.

Hose is made from Polypropylene fabric and films, films with PVC coated fabric cover, inner and outer wires are galvanized MS

Structure : Oil composite hose is composed of four parts: inner wire, cover, liner and outer wire

| Temperature Range | : | -20 °C to +80 °C |

These Oil Hoses are excellent for applications involving: