- Home

- Chemical Hose

- Home

- Products

- Industries

- Company

- Contact Us

- Home

- Products

- Industries

- Company

- Contact Us

Designed for suction and discharge of the most aggressive chemicals and searching solvents and is generally used where the chemical resistance of polypropylene is inadequate.

Chemical composite hose construction is very complex and is done in five layers : inner and outer helix, liner, carcass and cover.

| Inner Wire | : | SS 304 / SS 316 |

| Lining | : | Multiple layers of PTFE films |

| Carcass | : | Plies of Polypropylene films and fabrics |

| Cover | : | Weather resistant and anti-abrasive PVC |

| Outer Wire | : | Galvanised Steel / SS 304 / SS 316 |

| Temp. Range | : | -30°C to +80°C |

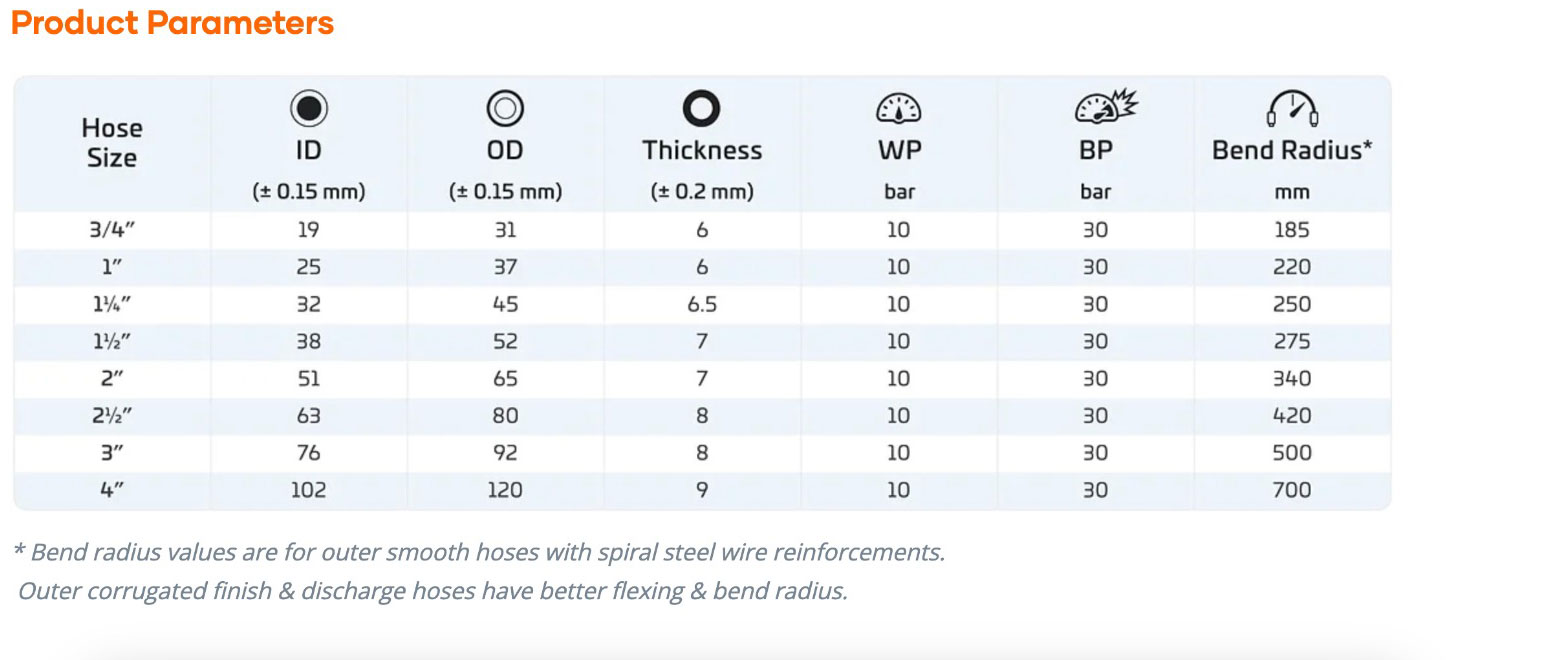

| Working pressure | : | 10 bar |

Chemical composite hoses are excellent for applications involving: