- Home

- PTFE Lined Thermoplastic Hose

- Home

- Products

- Industries

- Company

- Contact Us

- Home

- Products

- Industries

- Company

- Contact Us

Polytetrafluoroethylene (PTFE) is an engineered fluoropolymer, and has numerous applications. It has exceptional resistance to a wide variety of chemicals. PTFE Hose has increased resistance to vibration and flexing. PTFE Hose with a Polyurethane Jacket protects the stainless steel wire reinforcement against wear, fraying and contaminants.

PTFE hoses have exceptional chemical compatibility and handle temperatures as high as +450°F. PTFE Braided hoses are used in numerous applications including, but not limited to, chemical transfer lines, high temperature general hydraulics, and coolant lines. The PTFE core tube resists moisture and offers the lowest coefficient of friction of any known plastic, therefore minimizing pressure drops and deposits.

PTFE Hoses should be used when conveying non-conducting fluids such as oils, paints, fuels, or steam.

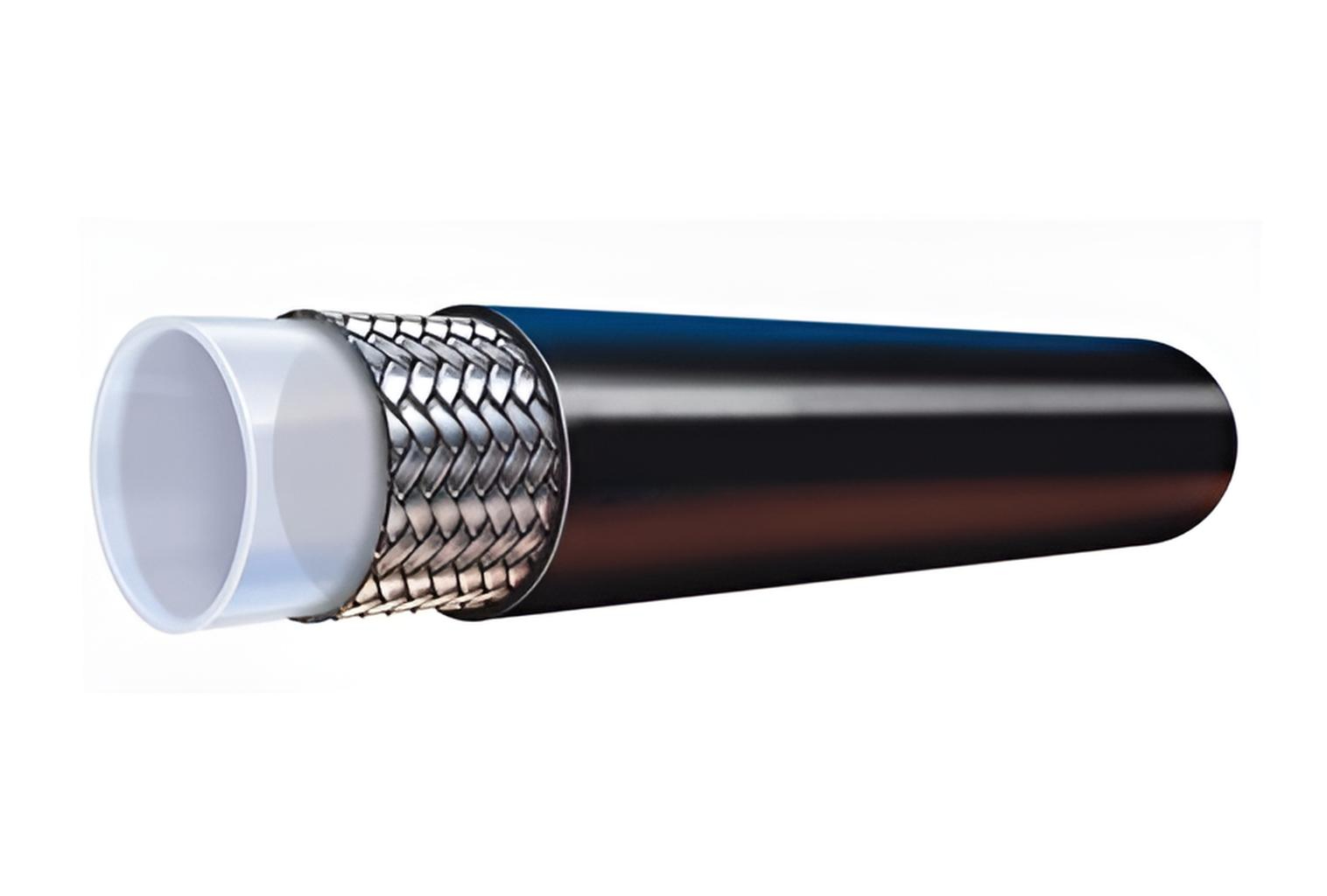

Inner core in PTFE, reinforcement in high tensile steel braid and external cover in anti abrasion pin-pricked polyurethane.

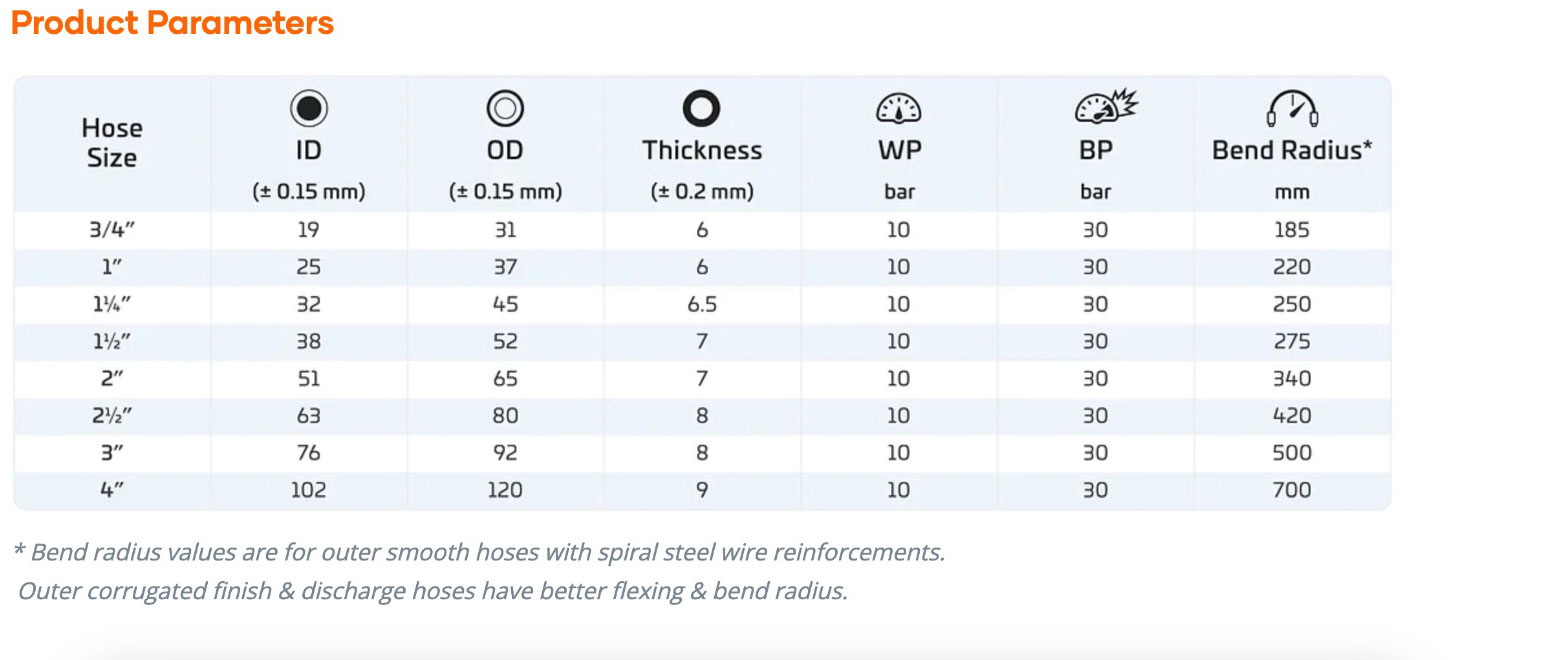

| Size | : | 3.5mm – 29mm |

| Tube | : | Natural FDA Compliant PTFE |

| Reinforcement | : | Braid of 304 Stainless Steel Braid |

| Cover | : | PVC/PU (Polyurethane) |

| Temperature | : | -100°F (-73°C) to 450°F (232°C) |

These PTFE Hoses are excellent for applications involving: